Address:Shitangwan Industrial Park,Huishan District,Wuxi City(Doumen)

Mob:0086-13961802200

Tel:0086-83558558/83557688

E-mail:zhangpeijie@

zhanghuayaoji.com

zqz008@126.com

Fax:0086-83558558-8000

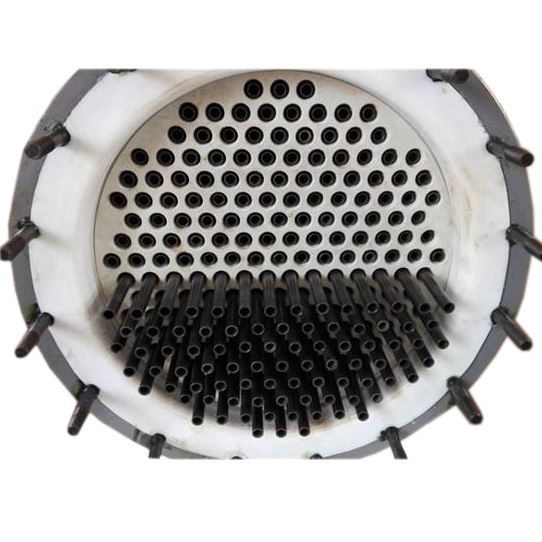

Silicon carbide heat exchanger is a new type of heat exchanger using silicon carbide ceramic material as heat transfer medium.Silicon carbide heat exchanger is an ideal choice for its acid and alkali corrosion resistance, oxidation resistance, wear resistance, high temperature resistance, high strength, high thermal conductivity and other properties.Suitable for high concentration sulfuric acid, nitric acid, hydrofluoric acid, mixed acid, sodium hydroxide, gas containing bromine and hydrogen bromide;Mainly used for heating, evaporation, cooling, condensation and heat recovery of materials.

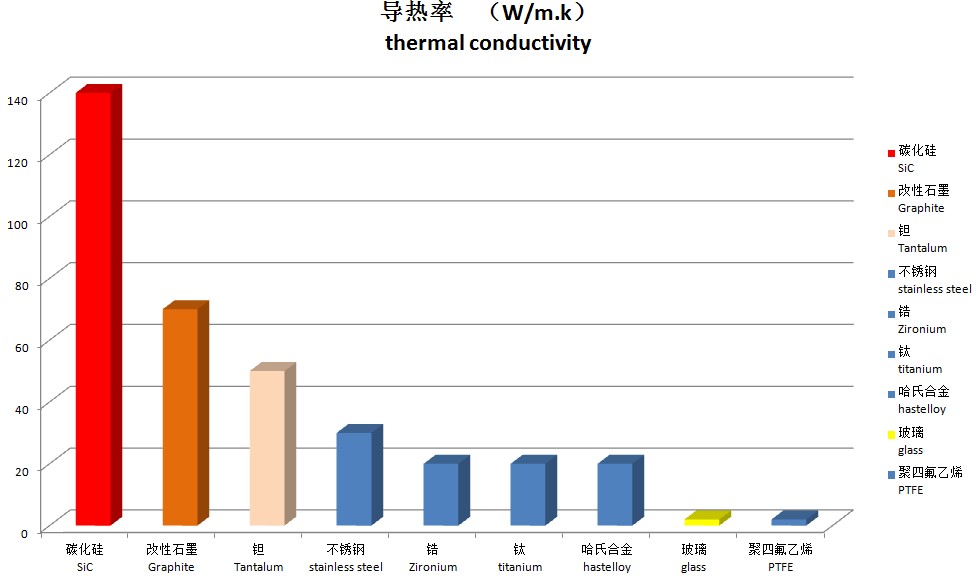

1、 Excellent thermal conductivity of SiC

2、 Corrosion resistance of SiC

corrosive medium

|

temperature (℃) |

(mg/cm2.Y) |

(mm/Y) |

98% H2SO4

|

100

|

0.98

|

0.0032

|

54% HF

|

25

|

0.06

|

0.0002

|

50%NaOH

|

100

|

1.25

|

0.0040

|

45%KOH

|

100

|

0.04

|

0.0001

|

70%HNO3

|

86

|

0.04

|

0.0001

|

37%HCl

|

25

|

0.07

|

0.0002

|

10%HF+HNO3

|

25

|

0.05

|

0.0002

|

10%HF+HNO3

|

120

|

1.25

|

0.0040

|

3、Characteristics of SiC Heat

exchanger

Excellent thermal conductivity

Widely corrosion resistance ability

Abrasion and erosion resistance, medium can with high speed

Good mechanical properties

No risk of contamination to medium

4、Our advantages for SiC Heat exchanger

Patent technology

Multiple choice for tubesheet,sigle tubesheet&multi-tubesheets,sigle tubesheet for commen condition, multi-tubesheets(Patent) significantly improves tube-plate rigidity, and greatly reduces the risk of leakage when under high temperature and high pressure

With solution of vibration and fracture to SiC tubes

Special design greatly reduces possible leakage points

Active leak prevention technology. the heat exchanger can still run normally even slight leakage happens to the gasket

Can be an independently heat exchanger , also can be used as internal parts

Experienced heat transfer calculation ability and research team

Strong technical team of anticorrosive equipment

Quick response after sales service

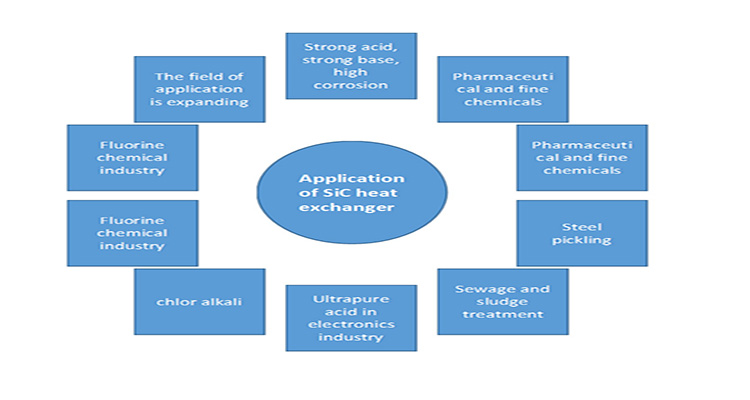

5、Main application of SiC Heat exchanger

6、Main material choice of SiC Heat exchanger

Corrosion side: glass-lined, plastic lining, glass reinforced plastics

Service side: carbon steel, stainless steel, enamel, lining plastic, fiberglass

Tubes:SiC

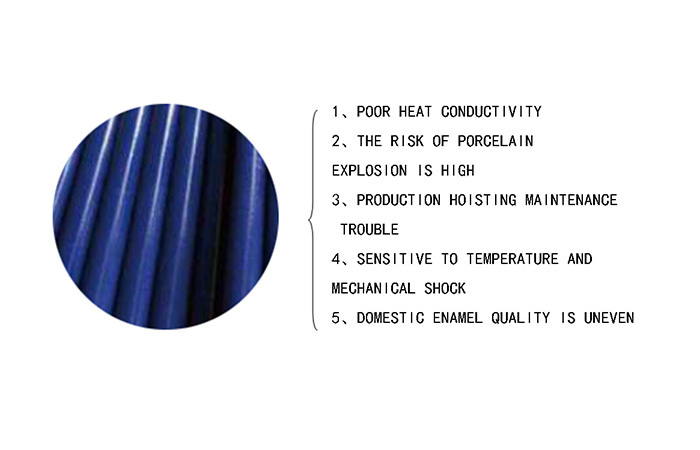

7、Shortcomings of other Heat exchangers

Shortcomings for glass-lined heat exchanger

Shortcomings for graphite Heat exchanger

Shortage of fluoroplastic Heat exchanger

Friendly reminder,each kind of anticorrosive material heat exchanger has its irreplaceable side, users needs to choose the best kind according to the process conditions.