Address:Shitangwan Industrial Park,Huishan District,Wuxi City(Doumen)

Mob:0086-13961802200

Tel:0086-83558558/83557688

E-mail:zhangpeijie@

zhanghuayaoji.com

zqz008@126.com

Fax:0086-83558558-8000

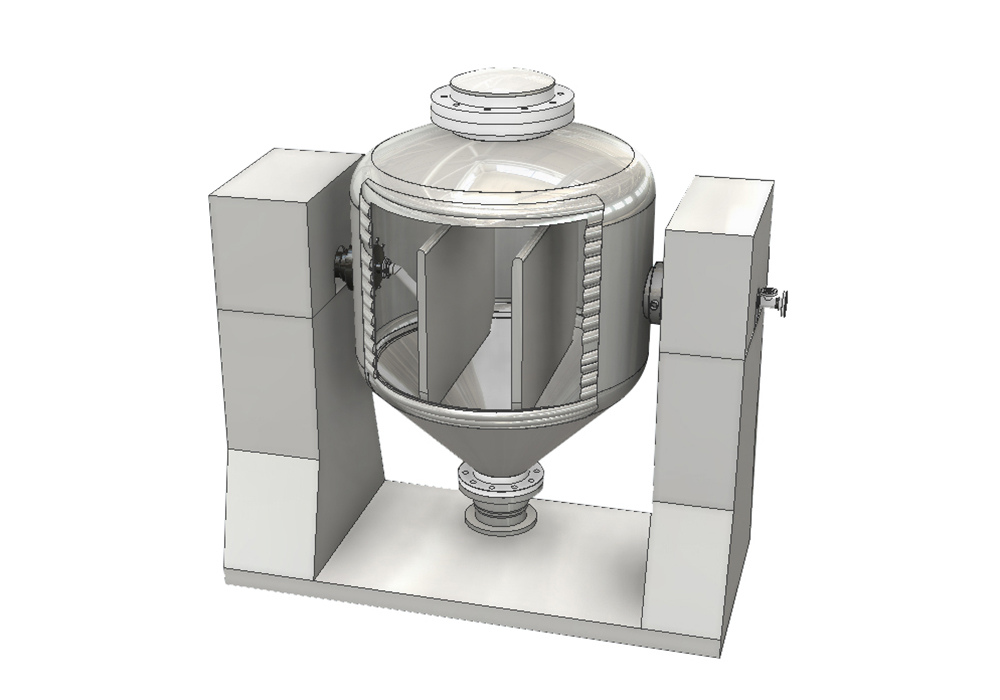

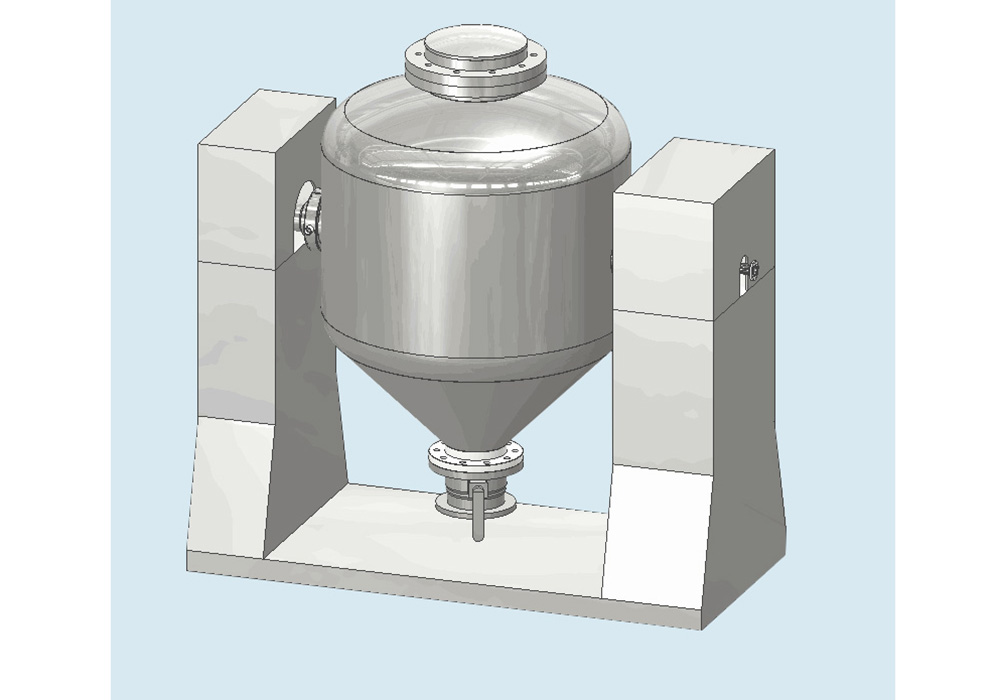

Working principle

Turn barrel to the horizontal position after feeding. At the same time, put refrigerant into jacket and internal heat conduction plate. Due to the direct contact between the heat plate and materials, heat exchange is uniform and fast, which not only improves the purity of materials, but also decrease the exchanging time and improve the productivity. After crystallization, switch on and rotate the equipment in 360°. Materials will be off from the barrel. Prepare for the next step to extract supernatant. The vacuum head is downward when you extract. After this step, adjust vacuum head upward. At the same time, switch on and rotate the equipment to make it vacuum and dry. When materials are dry enough, turn cone end downward, then completely discharge.

Usage

This crystallizer can be made from SS304, SS316L, Ti, Hastelloy, PTFE lined or other materials. It is mainly used for protecting crystal form of some materials, of which they have high requirements for crystals’ purity in the crystallizing process, from being destroyed, for example, refined naphthalene, borneol, Lithium Hexafluorophosphate, pharmaceutical, etc. Comparing with the traditional crystallizer, blade is unnecessary. Cone head design is for fully discharging.

Summary

Due to the particularity of the material, the traditional structure cannot guarantee the sufficiency of the material and uniformity of temperature in the tank, and the crystal form is not good enough. In order to improve the internal structure of traditional crystallization tanks, an internal heating board has been added in the tank to cool material down to a predetermined temperature in a short time. Comparing with the traditional jacket temperature control method, refrigerant is designed to flow through both jacket and internal heating board to optimize temperature control. The internal and external control design can ensure uniform temperature and form efficiently.

Features

Comparing with the traditional double cone type crystallizer, there is no filter plate needed in this equipment. In the vacuum head, we modify the design from traditional horizontal vacuum tube to a rotatable structure with a bent tube. When upward, it can be used for feeding. When it is downward, the supernatant can be extracted from the upper part of the crystal material. The new structure, instead of the original filter plate, can separate material from mother liquid. Due to the bent feed pipe upwards design, the loading coefficient can reach more than 65%, while the traditional horizontal vacuum tube design can reach below 50%.

| Specification(L) | Diameter of internal tank(φmm) | Diameter of jacket(φmm) | Heat preservation layer(φmm) | Motor power(KW) | speed |

| 500L | 850 | 920 | 60 | 2.2 | 5 |

| 1000L | 1040 | 1116 | 60 | 5.5 | 4 |

| 2000L | 1340 | 1416 | 60 | 7.5 | 4 |

| 3000L | 1600 | 1676 | 60 | 7.5 | 4 |

| 4000L | 1800 | 1866 | 60 | 11 | 3.2 |

| 5000L | 2000 | 2070 | 60 | 15 | 3.2 |

| 6000L | 2100 | 2184 | 60 | 15 | 3.2 |

| 7000L | 2200 | 2274 | 60 | 18.5 | 2.2 |

| 8000L | 2300 | 2380 | 60 | 18.5 | 2.2 |

| 10000L | 2400 | 2478 | 60 | 18.5 | 2.2 |

| 12000L | 2500 | 2580 | 60 | 22 | 2.2 |

| 14000L | 2600 | 2680 | 60 | 22 | 2.2 |

| 16000L | 2700 | 2780 | 60 | 22 | 2.2 |

| 18000L | 2800 | 2880 | 60 | 30 | 2.2 |

| 20000L | 2900 | 2980 | 60 | 30 | 2.2 |

| 25000L | 3200 | 3280 | 60 | 30 | 1.5 |

| 30000L | 3500 | 3580 | 60 | 37 | 1.5 |