Address:Shitangwan Industrial Park,Huishan District,Wuxi City(Doumen)

Mob:0086-13961802200

Tel:0086-83558558/83557688

E-mail:zhangpeijie@

zhanghuayaoji.com

zqz008@126.com

Fax:0086-83558558-8000

Usage

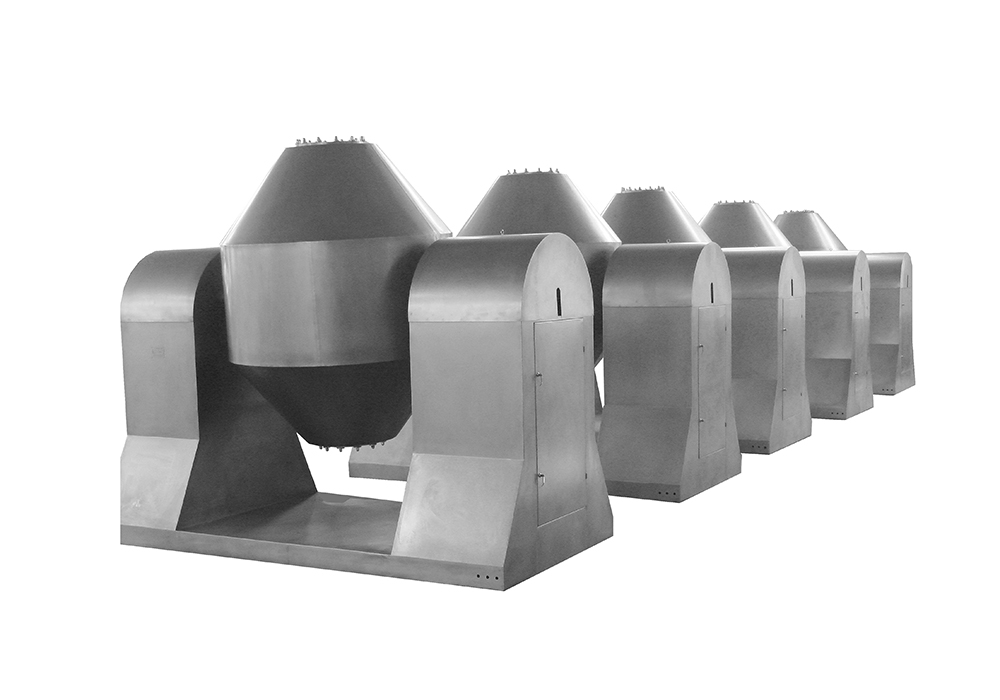

This series of products is one of the equipments that be researched and developed and been transferred by Shanghai Medical Industry Institute, mainly applicable for drying all kinds of granular materials, such as antibiotics, crystal, in the pharmaceutical, chemical and other industries.

Main characteristic:

1.The cone angle is designed as 60° which prevents materials from pilling during rotary process, and avoids powder retention during discharging.

2.The special design of vacuum pipes and vacuum filter increase the loading coefficient, which can even reach 65%.

3.The device includes three layers. The parts touching with materials can be made from SS304, SS316L, Ti, Hastelloy, PTFE lined or other materials. Jacket in the middle is for hot water circulation. To prevent stainless steel and carbon steel from producing static corrosion, the jacket must be made from stainless steel, and the outer layer uses fiberglass cotton for heat preservation.

3.High concentric degree of two shafts: less than 12um for 1000L or below, less than 16um for 1000L to 3000L, less than 25um for 3500L to 5000L.

4.Good stability: The whole frame is welded together with channel steel and carbon steel, outside covered with stainless steel plates.

5.Good sealing performance: concentric degree of shaft are controlled well, both ends use mechanical seal.

6.Good rigidity: Both ends of the cone are welded together with the cone vessel as a whole. It is not easy to be deformed.

7.Steady transmission: The whole unit is driven by the electrical motor, reducer, big and small gears, which enables the unit run more stably and reliably.

8.Mounted with CIP and SIP device.

9.Design with SIP, CIP dedicated device.

| Specification(L) | Capacity | Drive power | Rotate speed | Host weight | Diathermanous area of condensator(㎡) |

| 20L | ≤10 | 0.55 | 6 | 300 | 3 |

| 50L | ≤25 | 0.55 | 6 | 450 | 3 |

| 100L | ≤50 | 0.75 | 6 | 820 | 3 |

| 200L | ≤100 | 1.1 | 8 | 1050 | 3 |

| 300L | ≤150 | 1.1 | 5 | 1219 | 7 |

| 500L | ≤250 | 2.2 | 4 | 1674 | 7 |

| 750L | ≤370 | 2.2 | 3.5 | 1995 | 7 |

| 1000L | ≤500 | 7.5 | 4 | 3073 | 10 |

| 1200L | ≤600 | 7.5 | 4 | 3137 | 12 |

| 1400L | ≤700 | 7.5 | 4 | 3238 | 14 |

| 1600L | ≤800 | 7.5 | 4 | 3359 | 16 |

| 2000L | ≤1000 | 7.5 | 4 | 3570 | 20 |

| 2500L | ≤1250 | 7.5 | 4 | 4065 | 25 |

| 3000L | ≤1500 | 7.5 | 4 | 4565 | 30 |

| 3500L | ≤1750 | 11 | 4 | 7835 | 35 |

| 5000L | ≤2500 | 11 | 3.2 | 8347 | 50 |

| 6300L | ≤3150 | 15 | 3.2 | 9580 | 70 |

| 7000L | ≤3600 | 18.5 | 3.2 | 11500 | 70 |

| 8000L | ≤4000 | 22 | 2.2 | 12800 | 80 |

| 10000L | ≤5000 | 22 | 2.2 | 13900 | 100 |

| 12000L | ≤6000 | 22 | 2.2 | 14800 | 120 |

| 14000L | ≤7000 | 30 | 2.2 | 16200 | 140 |

| 16000L | ≤8000 | 30 | 2.2 | 18700 | 180 |

| 18000L | ≤9000 | 30 | 2.2 | 20150 | 200 |